|

| |

|

|

| There are very many glasses that can be used for making mirrors and we often get asked about the glass we use and which glass is really the best.

This page may not give you a perfect answer, but we hope it helps you understand the question. |

| |

| What may be best for one person may not be the right answer for another. The answer will depend to some extent on how much money is available and

what environment the mirror is to be used in. |

| |

| First Principles |

| The first thing to note is that a glass with good optical transmission properties is not necessary as light will not be travelling through the glass, it will be reflecting off the surface. Perhaps Cassegrain secondaries are excluded? See the testing page for an explanation. So all that is needed is a glass with

good physical properties, but that still leaves plenty of different glasses to choose from.

The second thing is cost and manufacture related. Most glasses used for astronomical purposes are a spin off from another major market. Plate glass has thousands of uses with windows being the most obvious. |

|

|

|

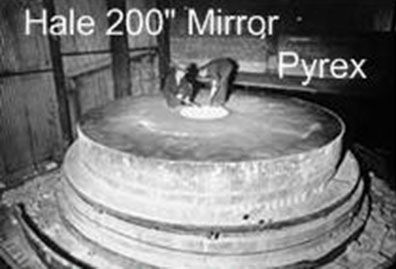

Suprax is used for high temperature lamps and laboratory glass-ware and Pyrex is used for millions of household and cooking utensils. Both are

trade names for what is really low expansion Borosilicate glass. They are well known by their trade names and the point is that it is large volume production in another market that drives down the cost of these glasses

and makes them available for the astronomical community at reasonable prices. |

|

|

|

Glass, Temperature & Distortion |

The main physical issue with glass for telescope mirrors is the distortion suffered when temperature changes. It is a fact of life that

all materials change their size to some extent when they change temperature and glass is no exception. |

| |

The amount of size change is always small, but can still be significant when compared with the wavelength of light. It is measured by the coefficient of thermal expansion and with glass it is generally measured in parts per million per degree centigrade or PPM/Deg C

for short. |

| |

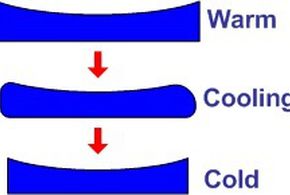

Where a glass mirror experiences a sudden change in temperature, such as moving your telescope from the house to the garden,

the glass close to the surface will adapt fairly quickly, but the glass deep inside the mirror will take longer to adapt. This will mean the mirror distorts and the parabolic curve on the mirror surface ripples out of shape until the temperature of the glass stabilises.

And you can forget about obtaining good images from your nominally 1/4 Wave mirror until it does! |

|

|

|

|

|

Opposite is an example of what happens to the mirror surface. Glass nearer the surface cools quicker

than inside. The corners cool faster than anywhere else. This example is an exaggeration as the real movements are microscopic, but it will be enough to disturb the images seen through the telescope

until the mirror temperature stabilises. |

| |

| The thicker the mirror, the longer it takes to adapt. Since larger mirrors have to be thicker for strength, larger mirrors take longer to stabilise. |

| |

| Different glasses have different coefficients of thermal expansion, so it is a good idea to use a low expansion glass with a very small coefficient if you can - then there is very little expansion to worry about. |

| |

| If a mirror is made of a glass that does suffer significant expansion, then the time the mirror will take to stabilise after a temperature change is affected by two other factors, the thermal conductivity and the specific heat. |

|

|

|

| Thermal conductivity means how fast heat travels through the glass, the faster it can travel, the faster the glass stabilises. Metals like copper have very high values. Unfortunately any

type of glass is very poor in comparison with metals. |

|

|

| Specific heat means how much heat energy is needed to be put into the glass to raise the temperature. This is a bit harder to explain. It is the capacity of the material to absorb heat.

A high specific heat means the glass takes longer to stabilise. |

|

|

| An analogy is with batteries. There are many different types and sizes of 9V batteries. Each will keep equipment like a transistor radio working for a different length of time depending

on its capacity. The higher the capacity, the longer the radio will keep running. |

|

|

| The capacity of the battery is analogous to specific heat in glass. The higher the specific heat, the longer the glass takes to stabilise after a temperature change. |

|

|

So in a glass for a mirror, we are ideally looking for a glass with a low coefficient of thermal expansion to limit the expansion suffered with temperature. As subsidiary factors may take

into account high thermal conductivity and low specific heat to reduce the time it takes for the glass

to stabilise. Finally - cost has to be a consideration. The mirror should be as cheap

as possible. |

|

|

| The Best Glass

for

proffesionals |

So what glass is best for primary mirrors? There is no one answer.

If the mirror is to be always kept and used in a temperature controlled environment 24 hours a day, or at least if the mirror can be allowed a fairly long time to settle down and equalise its temperature after being

moved, then you can't beat the cheapest glass available - plate glass. There would be no point in paying extra for anything else. |

|

|

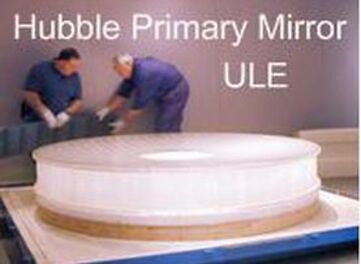

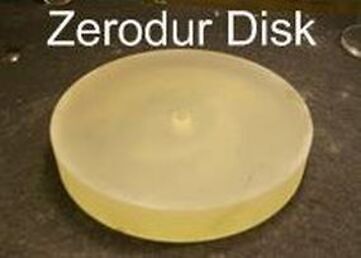

| If however you are building a space telescope; or are a professional astronomer affiliated with a large company or institute; or perhaps a very rich amateur where money is no object to you; or the mirror will typically be subject to large temperature changes, but is needed to be available for use as soon as possible - You may be considering Schott Zerodur, Corning ULE, fused silica or

a similar glass with an extremely low thermal expansion. |

|

|

|

|

|

|

|

|

|

|

The Best

Glass for

Amateurs |

If you are the typical amateur who keeps his telescope in the house and then either transports it to site in the back of a car, or perhaps just sets it

up in the back garden, then you may be looking for something between those two extremes - say a low expansion glass that is not that much

more expensive than plate glass? |

|

|

Don't worry! You are in very good company, the 200" Hale Telescope Mirror is Pyrex! In practice in the astronomical market, there is very little demand today for plate glass primary mirrors. This is even in the small sizes below 12" diameter where their thermal expansion does not cause

any practical problems. While we can produce plate glass mirrors if requested, we offer low expansion glass primary mirrors as standard. |

|

|

| If money is absolutely no object then Zerodur, ULE or similar glasses are the better choices as they have extremely low thermal expansions. |

|

|

| The thermal coefficients for Zerodur and ULE are 0.02 and 0.05PPM respectively - please do not compare them directly and automatically assume Zerodur is better. The values do

change with temperature and at one temperature ULE is zero. Both are so low that for use as a telescope mirror, any difference is of no consequence. |

|

|

| Even owners of mirrors made of Zerodur or ULE are not able to use their telescopes immediately after moving them out of a warm house into the garden. Although the mirrors would

suffer no distortion throughout the cooling period, there would still be a temperature change to deal with. Convection from the warm surfaces causes air currents that distort the viewing

until the mirror has cooled. |

|

|

| The same applies to the metal or wood structure of the telescope itself- that would need to cool down before air convection currents

die away. Taking those factors into account - it might be a bit pointless paying extra for a Zerodur or ULE mirror? These glasses

would not generally be considered good value for money by most informed amateurs. |

|

|

In practice, for small mirrors up to say 12" diameter, even a plate glass mirror can cool down sufficiently before convection currents from the rest

of the telescope structure die away to allow good viewing, but we now offer low expansion glass as standard. |

|

|

There is really very little to chose between Pyrex, Suprax or Supremax. All three are very similar Borosilicate glasses from two

different manufacturers using two different casting processes. Pyrex and Supremax have nominally lower thermal coefficient of expansion than Suprax,

so on face value look better, though Suprax cools down marginally faster and is about 20% cheaper. Supremax costs more than Pyrex, but can

be available with shorter delivery dates. |

|

|

As a practical example of a low expansion glass cooling, a 16" (400mm) diameter mirror made of 40mm thick Pyrex and manufactured to 1/6λ,

was allowed to stabilise at about

10 degrees above the workshop temperature. It was then brought into the workshop and tested over a period of time as it adapted to the new temperature. It rapidly exhibited about

1/2λ of error, and took about 30 minutes to return under 1/6λ. You may expect similar times following transport of a telescope to site in the back of a car. |

|

|

Note that the main markets for Pyrex and Suprax are in household and laboratory glassware respectively. Blanks are readily available up to about

5-600mm diameter, but sizes bigger

than this are rarer and more expensive as their main markets do not require them. Consequently there is a large step change in price at about this diameter. The thickness of a large

blank may vary within a few millimetres depending on the supplier. |

|

|

|

Cassegrain Secondary Mirrors |

| After reading values in the table, some of you considering a Cassegrain might be worried by the high thermal expansion value of BK7 glass that Oldham Optical use for Cassegrain secondary mirrors. Don't forget that even though the thermal expansion of BK7 is twice that of Pyrex/Supremax, the secondary mirror is less than half as thick as the primary.

Even with the higher coefficient it will have stabilised before the primary mirror. |

|

|

|

Elliptical Flats |

| For a similar reason, we consider Plate Glass is perfectly adequate for elliptical flats in Newtonians. The flats are only a fraction of the size and thickness of the main mirror and will

always stabilise before the main mirror does. However if a customer wishes the flat to be of low expansion glass, we have no problems supplying - just make sure we know what you want. |

|

|

|

Normal

Glass |

| Primary mirrors for Newtonians and Cassegrains will be low expansion glass from either Pyrex, Suprax or Supremax, mostly depending on levels in stock or availability at the time the order is placed. If you have a preference for one particular glass, please discuss it with us or make it clear what you want in your order. |

|

|

| Cassegrain secondary mirrors are usually BK7. |

|

|

| Elliptical flats are usually plate glass. |

|

|

| Note that for primary mirrors above about 450mm diameter, the exact thickness supplied will vary slightly depending on the type of glass and the source it is obtained from.

|

|

|

|

|

| |